Simulation

Package

Short Description

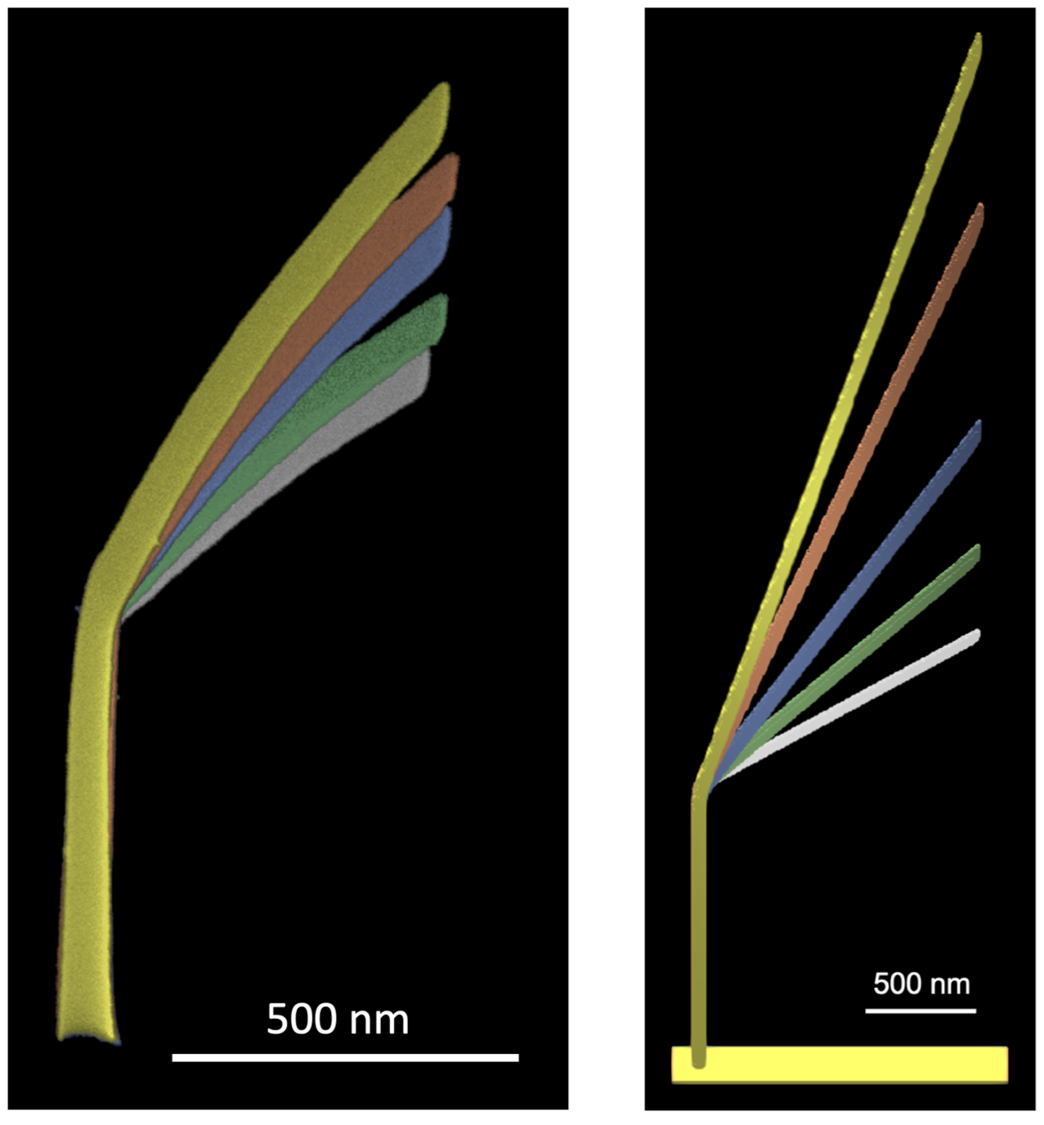

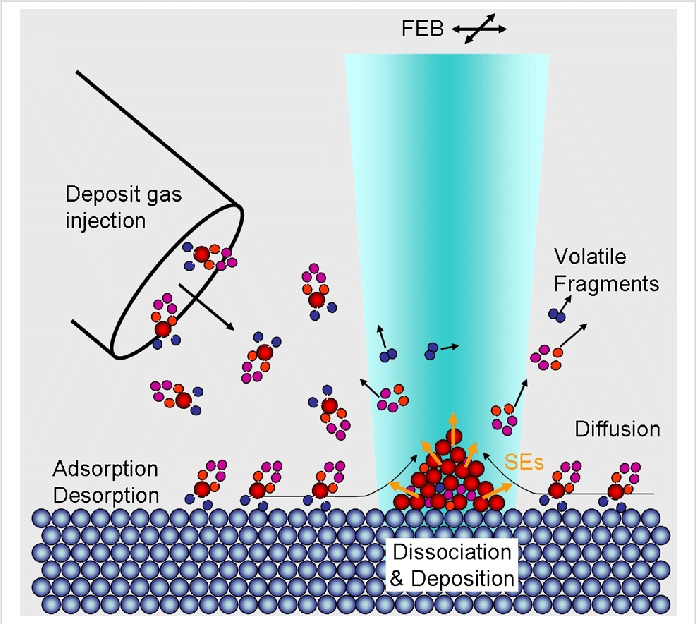

A fast and modular simulation platform for Focused Electron Beam Induced Deposition (FEBID) — now including thermal effects. This Python-based tool enables users to predict 3D growth behavior, optimize pattern files, and analyze shape fidelity by accounting for electron scattering, precursor dynamics, and beam-induced heating. Its hybrid Monte Carlo–continuum approach supports advanced applications like pattern slicing, growth parameter estimation, and co-deposit analysis, making it ideal for accelerating experimental design and reducing trial-and-error iterations.

The FEBID continuum simulation code is a powerful tool designed to model the complex interplay between precursor gas dynamics, electron interactions, and material deposition during Focused Electron Beam Induced Deposition (FEBID) processes. By solving the governing equations for gas flow, surface reactions, and electron scattering, the code provides detailed predictions of nanostructure growth rates, geometries, and material compositions. This enables researchers to optimize deposition parameters, improve process efficiency, and achieve precise control over nanoscale fabrication. With its robust modeling capabilities, the code serves as an essential resource for advancing FEBID-based nanotechnology.

The gas injection simulator is an advanced computational tool designed to optimize gas delivery for Focused Electron and Ion Beam Induced Deposition (FEBID/FIBID) processes. By accurately modeling molecule flux distributions on substrates, the simulator evaluates various nozzle geometries, such as straight, bevelled, and perforated designs, to maximize gas efficiency and deposition precision. Using a robust Monte Carlo method, it accounts for critical factors like gas flow dynamics and operational configurations, enabling users to fine-tune parameters for enhanced uniformity and performance. This tool provides invaluable insights for researchers and engineers seeking to push the boundaries of nanoscale fabrication.

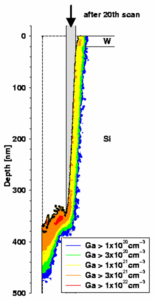

This simulation package is designed for precise modeling of ion-solid interactions during Focused Ion Beam (FIB) processing. It enables detailed simulations of material sputtering, ion implantation, and surface morphology evolution, providing critical insights into processes like milling, deposition, and ion-induced modifications. By accurately predicting ion distributions, material removal rates, and secondary emissions, the tool supports the optimization of FIB parameters for high-resolution nanoscale fabrication. Its robust computational approach makes it an essential resource for researchers and engineers aiming to refine and innovate in ion-based nanotechnology.