Precision Redefined: Advanced Techniques for Nanoscale Material Removal

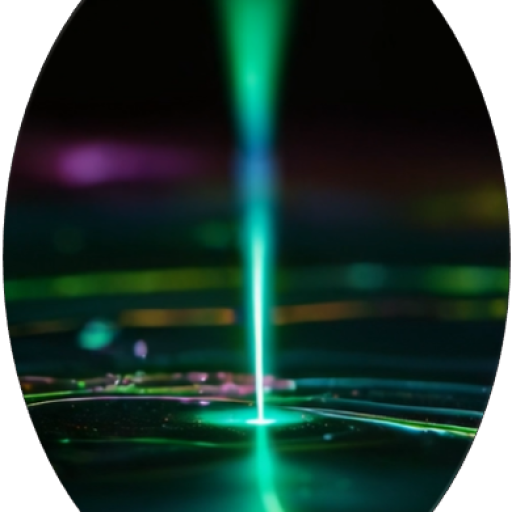

Achieving nanoscale precision in subtractive material sculpting is realized through advanced removal techniques such as FIB milling, FEBIE, and FIBIE. These state-of-the-art methods enable the controlled reshaping, refinement, and optimization of materials with exceptional accuracy, pushing the boundaries of what is achievable in nanofabrication.

- FIB Milling: Harness the force of high-energy ions to carve intricate patterns and deep features with nanometer accuracy.

- FEBIE (Focused Electron Beam Induced Etching): Unlock the magic of electron-beam-induced etching to selectively remove material while preserving even the most delicate structures.

- FIBIE (Focused Ion Beam Induced Etching): Experience the best of both worlds with ion-beam etching enhanced by reactive gases for unparalleled efficiency and selectivity.

These tools don’t just remove material – they open a gateway to limitless possibilities, empowering breakthroughs in semiconductors, advanced optics, and next-generation devices.

Literature

Roadmap for Focused Ion Beam Technologies; K. Höflich et al.; Appl. Phys. Rev (2023), 10, 041311.

Advances in Gas-Mediated Electron Beam-Induced Etching and Related Material Processing Techniques; M. Toth; Appl. Phys. A (2014) 117:1623

Nanofabrication Using Focused Ion and Electron Beams: Principles and Applications; I. Utke, S. Moshkalev S., P. Russell P.; Oxford: Oxford University Press (2012)

Ions and Electrons: A Dynamic Duo for Precision Material Removal

At the heart of material removal lies the unique interplay of ions and electrons, each bringing distinct advantages to direct-write nanofabrication. Focused Ion Beams (FIBs) excel in precision physical sputtering, where high-energy ions physically remove material step by step. This technique achieves exceptional accuracy, ideal for milling complex geometries or correcting nanoscale defects. The addition of reactive gases during FIB processes, denoted as Focused Ion Beam Induced Etching (FIBIE), further enhances etching selectivity and efficiency by facilitating targeted chemical reactions, reducing unintended damage to surrounding areas. In contrast, Focused Electron Beam Induced Etching (FEBIE) offers a less invasive approach by leveraging the chemical energy of reactive gases activated by an electron beam. This process minimizes the physical sputtering contributions, preserving the integrity of delicate structures. FEBIE’s reduced thermal impact also makes it particularly suitable for applications where heat-sensitive materials or fine features demand the utmost care. Together, these techniques provide a versatile toolkit for achieving precision removal while catering to diverse material and design requirements.

Literature

Roadmap for Focused Ion Beam Technologies; K. Höflich et al.; Appl. Phys. Rev (2023), 10, 041311.

Advances in Gas-Mediated Electron Beam-Induced Etching and Related Material Processing Techniques; M. Toth; Appl. Phys. A (2014) 117:1623

Nanofabrication Using Focused Ion and Electron Beams: Principles and Applications; I. Utke, S. Moshkalev S., P. Russell P.; Oxford: Oxford University Press (2012)

Cutting-Edge Tools: Empowering Precision in Nanoscale Material Removal

Material removal using direct-write technologies relies on FIB-SEM dual-beam systems, optionally equipped with Gas Injection Systems (GIS) for delivering reactive gases and patterning engines for precise control. For FEBIE-specific tasks, standalone SEMs with GIS capabilities are often sufficient to achieve high precision. However, applications requiring hybrid approaches, such as combining FIB milling with chemical etching, benefit from state-of-the-art dual-beam systems featuring multiple GIS units to accommodate a broader range of etching processes. The growing availability of FIB-SEM systems in research and industrial laboratories worldwide ensures that this powerful technology is increasingly within reach.

Manufacturers

Hitachi Microscopy, JEOL Microscopy, Orsay Physics, Raith, TESCAN, Thermo Fisher Scientific, Zeiss Microscopy