Shaping the Future: The Power of Direct-Write Technologies

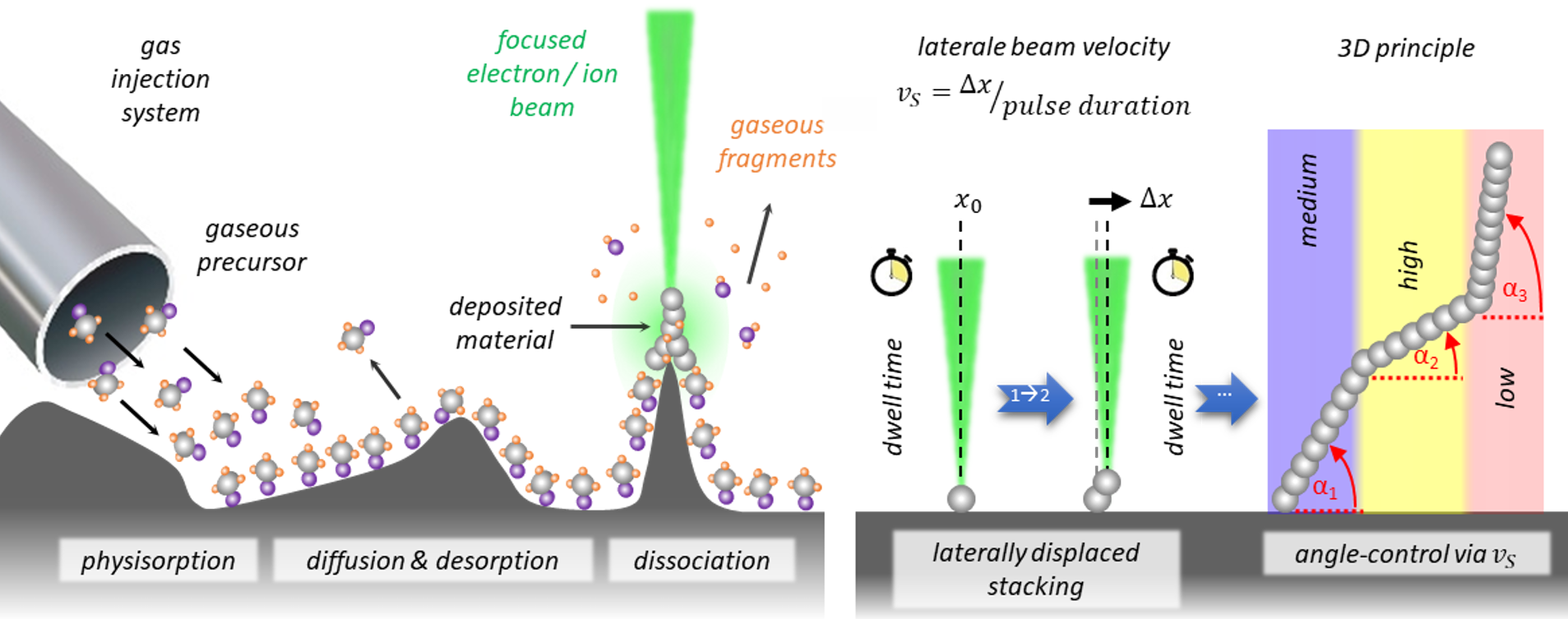

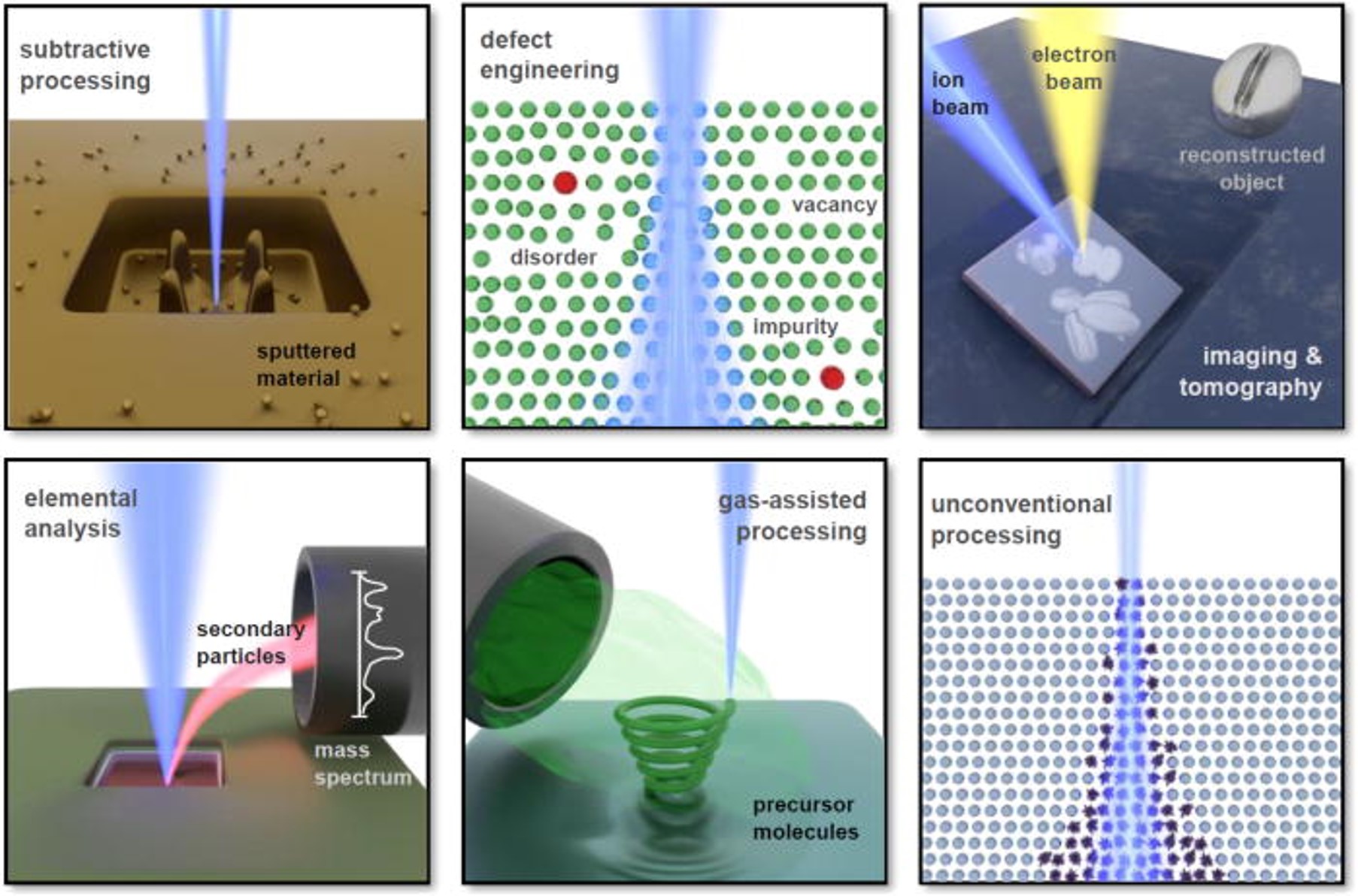

Direct-write nanomanufacturing merges precision, flexibility, and speed – using focused electron beams and both established and novel ion beams to directly deposit, remove, and modify matter down to the lowest nanometer scale. Without masks or templates, it enables fully customizable structures and localized tuning of functional properties on practically any surface with unmatched spatial precision.

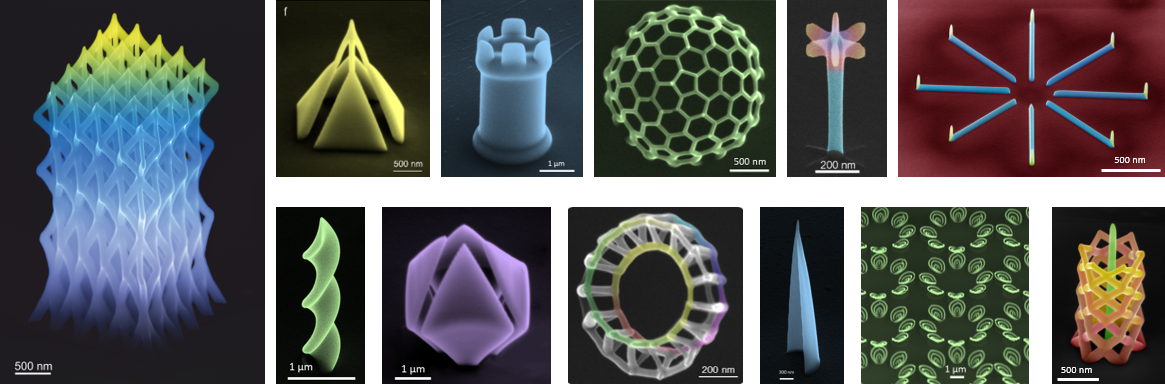

What truly sets this technology pool apart is the ability to fabricate true 3D geometries – not just stacked layers, but freeform architectures that can merge additive, subtractive, and modification processes within continuous workflows under ideal conditions. Through multi-material integration, it becomes possible to combine metallic, semiconducting, insulating, magnetic, superconducting, or optical functionalities within a single object – creating structures that unite multifunctional elements in three dimensions, an advantage practically inaccessible to alternative technologies at this scale.

Beyond performance, direct-write nanomanufacturing is both rapid and resource-efficient, minimizing material waste while seamlessly linking nanoscale and microscale fabrication within hybrid workflows to either bridge distinct length scales or expand the integration of additional functionalities across diverse design concepts.

Whether in applications such as nanoelectronics, quantum technologies, microrobotics, sensors, life sciences, or other emerging fields yet to come, this technology pool defines a new paradigm – one that expands the boundaries of what is physically and functionally possible at the nanoscale in 3D space.

Literature

A Review on Direct-Write Nanoprinting of Functional 3D Structures with Focused Electron Beams; V. Reisecker, R. Winkler, H. Plank; Adv. Funct. Mater. (2024), 34, 2407567.

Roadmap for Focused Ion Beam Technologies; K. Höflich et al.; Appl. Phys. Rev (2023), 10, 041311.

Living Up to Its Potential – Direct-Write Nanofabrication with Focused Electron Beams; M. Huth, F. Porrati, S. Barth; J. Appl. Phys. (2021), 130, 170901.

Concept of Focused Electron / Ion Beam Induced Deposition (FEBID / FIBID) for additive direct-write nano-manufacturing (left) and its possibility to create freestanding 3D nanoarchitectures (right).

Examples of complex 3D nanostructures with individual feature sizes down to the sub-50 nm regime.

Shematic overview of different FIB approaches. Adapted from Katja Höflich et al., Appl. Phys. Rev. 2023, 10, 041311. Licensed under CC BY 4.0.