Unlocking New Frontiers with Direct-Write Technologies

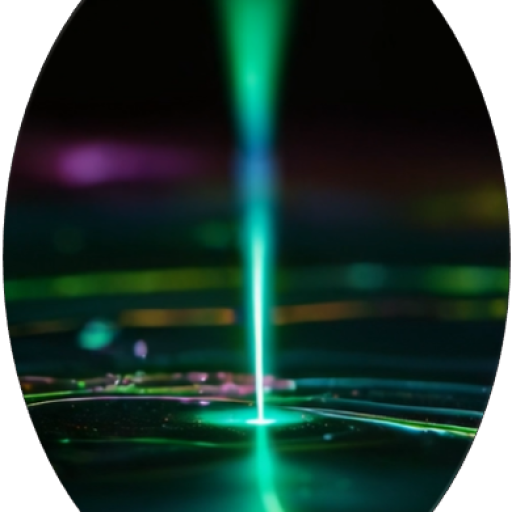

Direct-write technologies redefine what’s possible in nanomanufacturing by enabling the direct placement, removal, and modification of materials — all with true nanoscale precision and on virtually any surface. By harnessing focused electron and ion beams, these methods eliminate the need for masks or templates and deliver unmatched control at the smallest scales.

What sets this approach apart is its ability to fabricate true 3D architectures — not just layer-by-layer, but fully freeform structures with nanometer accuracy. This capability expands even further through hybrid strategies, including temperature control, reactive gas exposure, or post-growth treatments like CVD and ALD. The result: functional, application-specific nanosystems beyond the reach of traditional methods.

Whether engineering magnetic domains, tailoring optical responses, crafting precision sensors, producing supercondiúcting elements or pushing nanoelectronics and energy technologies, direct-write fabrication empowers breakthroughs across disciplines.

With its 3D freedom, nanoscale resolution, and versatile direct-write capabilities, this technology pool stands as a foundation for the next generation of scientific and industrial innovation.

Literature

A Review on Direct-Write Nanoprinting of Functional 3D Structures with Focused Electron Beams; V. Reisecker, R. Winkler, H. Plank; Adv. Funct. Mater. (2024), 34, 2407567.

Roadmap for Focused Ion Beam Technologies; K. Höflich et al.; Appl. Phys. Rev (2023), 10, 041311.

Living up to its Potential – Direct-Write Nanofabrication with Focused Electron Beams; M. Huth, F. Porrati, S. Barth; J. Appl. Phys. (2021), 130, 170901.

Focused Electron Beam Induced Deposition Meets Materials Science; M. Huth, F. Porrati, O.V. Dobrovolskiy; Microelectronic Engineering (2018), 185, 9.

Adapted from Verena Reisecker et al., Adv. Funct. Mater. 2024, 34, 2407567. Licensed under CC BY 4.0.